Professional Cable Lug & Terminal Manufacturer from China

Since 2012 • UL Certified • OEM/ODM Available

Since 2012 • UL Certified • OEM/ODM Available

Engineered for secure, low-resistance electrical connections in high-current environments, our UL-certified compression connectors deliver superior conductivity, long-term durability, and precision fit. Ideal for industrial, energy, and automotive applications.

Available with color-coded ends for easy identification.

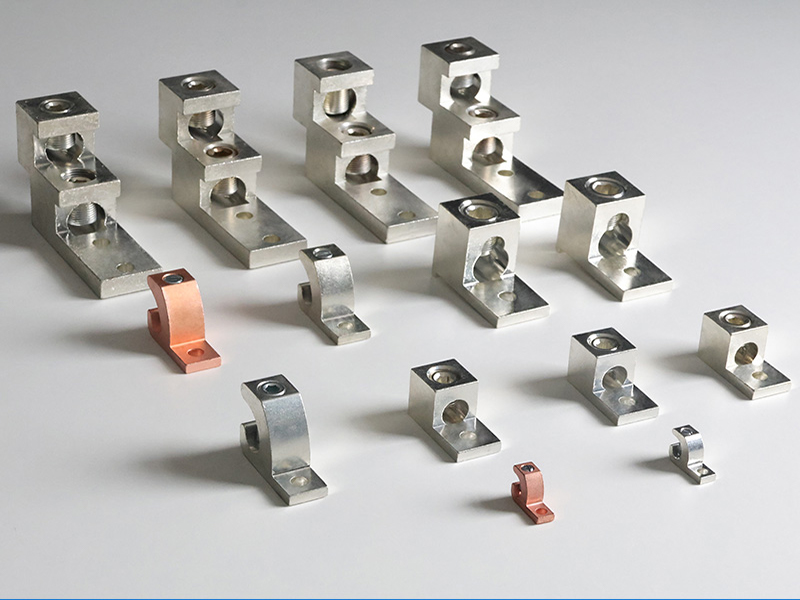

Designed for quick installation and reliable conductivity, our mechanical connectors ensure high-performance electrical bonding without the need for crimping or welding. Built to UL standards and ideal for a wide range of industrial, utility, and power distribution systems.

Durable construction and corrosion-resistant finishes for long service life.

Our insulated terminals offer safe, secure, and color-coded connections for a wide range of wiring applications. Manufactured to UL standards, they ensure optimal electrical insulation, strain relief, and long-term reliability in demanding environments.

Available in vinyl, nylon, and heat-shrink insulation types for various wire gauges.

Crafted from high-conductivity electrolytic copper, our tubular lugs ensure efficient power transmission and low contact resistance in heavy-duty electrical installations. UL-certified and precision-engineered, they support secure crimping and long-term performance in power distribution, switchgear, and industrial control systems.

Tin-plated finish for corrosion resistance and enhanced conductivity.

Engineered for permanent, high-integrity connections, our uninsulated solder terminals provide excellent conductivity and a compact profile for confined wiring spaces. Made from high-purity copper with optional tin plating, these terminals are ideal for applications requiring strong mechanical bonds without added insulation.

Suitable for automotive, electronics, and precision wiring assemblies.

Our rolled terminals are designed in continuous strip format for seamless integration with automated crimping machines—maximizing production speed and consistency. Ideal for high-volume wiring harness assembly, these precision-stamped terminals ensure stable quality and reduced handling time.

Optimized for automated lines to improve manufacturing efficiency and reduce labor costs.

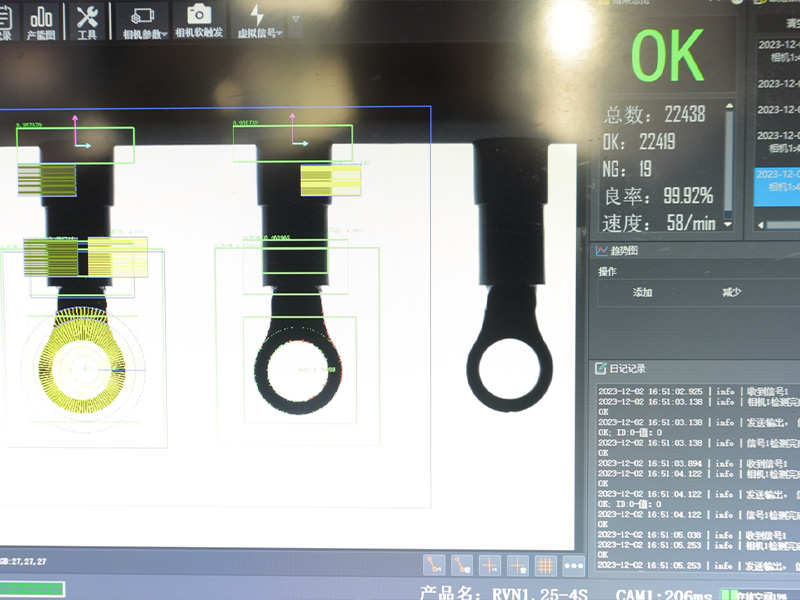

Full control over stamping, manufacturing, and testing in our own facility ensures consistent quality, reliability, and performance across every batch.

From 3D design to physical sample in just 5 days—ensuring you can evaluate before production without long delays in your development schedule.

Certified to UL and CE RoHS Reach standards to meet international safety and environmental regulations—providing peace of mind across global markets.

We tailor connectors, terminals, and accessories to your branding, dimensions, and functional requirements—supporting your unique design needs.

Extensive inventory of standard terminals ready to ship—minimizing downtime and keeping your production or supply chain on schedule.

With over 15 years of industry experience, we combine expertise, advanced stamping technology, and rigorous testing capabilities to deliver dependable electrical connection solutions that exceed global quality standards.

Our vertical integration—from design to delivery—enables rapid sample production, flexible customization, and bulk order fulfillment designed to support your industrial, automotive, or power engineering supply needs.

“LAIDU’s fast 5‑day prototyping process saved our engineering team weeks. Their UL-certified crimp terminals performed perfectly in our electrical distribution panels. Reliable quality and excellent communication.”

Maintenance Director, Power Engineering OEM

“We ordered custom cable lugs in bulk for our telecom deployments. LAIDU’s in-house production and flexible OEM service ensured we met tight deadlines with flawless components.”

Procurement Manager, Telecom Integrator

“As a solar energy systems provider, we rely on insulated and copper battery terminals. LAIDU’s large inventory and UL/RoHS compliance helped us scale quickly and securely.”

Operations Lead, Solar Solutions Company

The following are some frequently asked questions about the wholesale and service of terminal blocks, if you can't find what you are looking for, please contact us.

You can provide us with your drawings and we will produce according to them. Alternatively, if you don't have a clear plan, we can design it.

TT and L/C are acceptable, but TT is preferred. A 50% deposit is required before production, and a 50% balance is required before loading.

It depends on the order quantity. Generally, delivery time is between 7 and 30 days.

A: Inner boxes and master cartons are manufactured according to international standards. If necessary, we can create a custom design for you. If necessary, they will be packaged on pallets to avoid any damage.

B: Each carton does not exceed 35 kg, and each pallet is approximately 1000 kg.

7 days, depends on the complexity of the sample. Normally, our samples are free of charge.

Yes—our factory capacity and stocked inventory allow us to fulfill bulk and wholesale orders quickly and cost‑effectively.

Leave your phone number and email id in the box below and our investment relationship manager will get in touch with you.

We turn complex Into Simple! Follow the following 3 steps to start today!

Send us your inquiry and we will get back to you shortly!